Submitted by Greg Conder, P.E.

Late deliveries of precision machined and fabricated components can have a negative and cascading effect on a business’ product flow, customer service and profits. Also, late deliveries from suppliers can make the buyer or purchasing agent look bad to their leaders.

Product Flow and Financial Impacts

The custom components we manufacture may be a small part of the overall assembly. However, without these components our customers can not complete and deliver their valuable assemblies. This has a negative effect on cash flow, inventory utilization, work in process and customer service.

Impacts to the Buyer or Purchasing Agent

Stated plainly, no buyer of purchasing agent wants to be called out in a meeting where one of their suppliers is holding up production. Sometimes, the buyer’s job could even be on the line.

C&C Machine

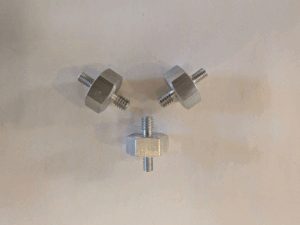

We have more than 35 years of experience in providing custom machined components like bus bars and heat sinks. These, along with other components, typically are part of assemblies and sub-assemblies for our customers. We have an excellent understanding of the impact of late deliveries. Therefore, we strive to have zero late deliveries. We work closely with our customers and their often-changing production schedules.

Consider this recent communication from one of our customers:

I can’t express how grateful I am for all of your help. The Production Manager is happy and you just saved the day again. In our production meeting, another buyer that you have helped said “you just can’t beat C&C Machine”. Our whole team is beyond appreciative.