A great deal of copper is used in medical equipment. From equipment like MRI machines to copper tubing that carries medical gases.

Hospital facilities also utilize copper in ways that are standard in many buildings. Uses like plumbing, HVAC systems and electrical wiring.

Why is so much copper used in medical equipment?

Conductivity

Copper has excellent conductivity properties which makes it an excellent material choice for medical equipment that involves a lot of electrical components like motors, wiring, connectors and bus bars. Equipment like MRI machines and heart defibrillators use a great deal of copper.

Electromagnetic Interference Shielding

Electromagnetic and radio frequency interference can cause sensitive medical equipment to malfunction. Shielding keeps the frequency waves from other equipment or devices from entering the sensitive medical equipment.

The best shielding materials have high electrical conductivity properties; therefore, copper is a good material choice for shielding purposes.

Related: Demand for Copper Expected to Increase Through 2030

Non-Flammable and Clean

Copper has a very high melting point and is considered clean for uses such as piping and tubing. This high melting point makes it less likely to burn like some plastics. For these reasons, copper is used to dispense oxygen and other medical gases.

Antimicrobial Properties

According to the American Society for Microbiology, copper has antimicrobial and wound healing properties. Research is being conducted to see if copper-coated surfaces can be helpful in clinical settings by reducing the growth and spread of germs that cause infection.

Hard surfaces tested include door knobs, handles and toilet seats. Soft surfaces tested include socks and sheets.

Copper is used in medical equipment because copper is highly conductive, non-flammable and has antimicrobial properties.

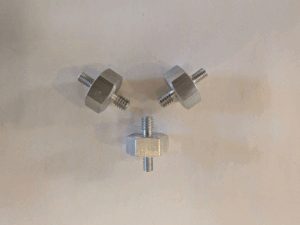

About C&C Machine

We are a precision CNC machine shop located in Oklahoma. We have been manufacturing components from copper and other materials for 45 years.