Naval brass is used in marine environments because it has a high resistance to corrosion. Brass alloys 464 and 485 falls into the naval brass category. Alloy 485 has better machinability characteristics because it has a slightly higher lead content.

Brass alloy 360 is a more common alloy. It is easily machined but does not have the corrosion resistance of naval brass. Naval brass has a higher content on of zinc and tin leading to corrosion resistance characteristics.

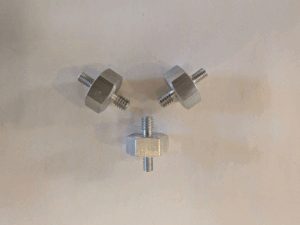

We recently had the opportunity to machine some valve fittings and components for one of our customers using naval brass, alloy 485. It was a relatively low-volume order of 15 pieces each. Of course, we utilized our CNC mills and lathes.

For one of the components, we used our special knurling tool. We had yet another happy customer!